Training and Placement of Eyewashes and Emergency Showers Critical to Worker Safety

The distance from a corrosive material to an eyewash and emergency shower needs to be no more than 10 seconds. That’s according to the Occupational Safety and Health Administration (OSHA).

It can be difficult, however, to decide where exactly those eyewashes and emergency showers need to be placed. That’s because it is sometimes difficult to pinpoint exactly what constitutes a corrosive material. While some corrosive materials are obvious, others are not so obvious.

What follows are some of the areas you might not expect to house corrosive materials:

- Battery charging stations: Charging batteries is something many people associate only with cars and other vehicles. However, batteries are charged in a variety of other places, as well. Forklifts, aerial lifts and other types of equipment have batteries that need to be charged. Cell phone towers are another overlooked place where batteries are charged. Finally, commercial and manufacturing facilities service and handle batteries frequently.

- Retail stores: Drug stores and other types of grocery and warehouse stores often have photo processing centers that contain huge quantities of developers, fixers and rinses that can be extremely corrosive.

- Maintenance closets: Think of the many chemicals in a janitor’s closet, for example, bleach, grout, tile cleaner, floor strippers and drain cleaners. Depending on the facility, other dangerous chemicals also may be present. At pools, chlorine and bleach are commonly found in a janitor’s closet. Hotel and restaurant kitchens hold kitchen cleaners, sanitizers and degreasers. Hospital janitor closets are another danger zone.

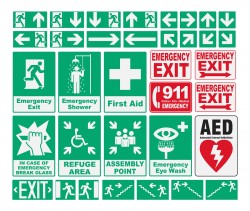

While the Code of Federal Regulations, Title 29, section 1910.151(c) states “Where the eyes or body of any person may be exposed to injurious corrosive materials, suitable facilities for quick drenching or flushing of the eyes and body shall be provided within the work area for immediate emergency use,” this regulation raises some very important questions. What is immediate and suitable? What are flow requirements? How often should testing occur?

In order for workers to remain safe, it is imperative that a safety audit takes place by a trained safety services professional. This will ensure that all requirements for eyewashes and emergency showers are met—from water temperature to fluid replacement.

Further, ongoing safety training must be offered to employees who work in these areas. While it is one thing for employees to know where eyewashes and emergency showers are located, they need to be able to use them correctly in critical situations. If they are unable to do so, the result could be catastrophic.